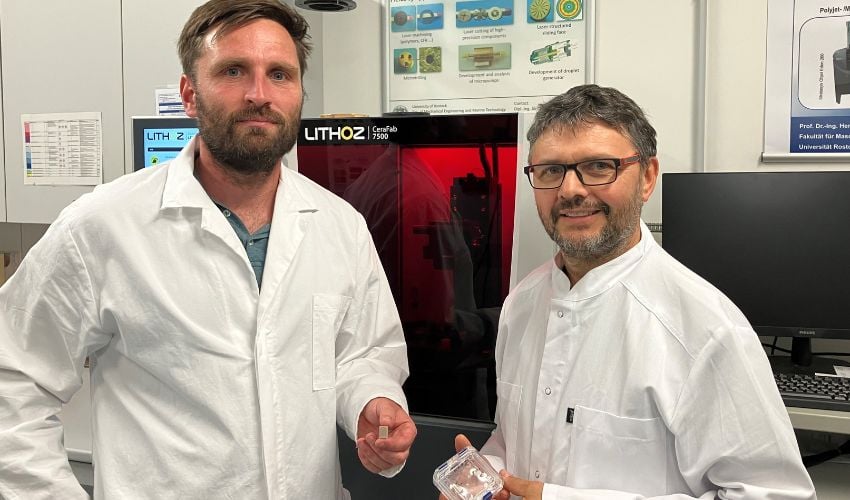

Bones have a high degree of self-healing capacity. It is for that reason that with bone fractures, which may come about after a skiing accident, bicycle fall or mishap, the bones are usually able to grow back together themselves. Although how long that may take varies depending on age and severity of the fracture, among other factors. However, if larger bone defects occur as a result of tumors, the bone can no longer regenerate itself. In this case, implants are used, usually made of titanium or the patient’s own bone material from other parts of the body. Now, 3D printing is the latest technology to be used. At University of Rostock, one research project is looking into the production of bioactive bone replacement structures. Specifically, this is the ELAINE – Electrically Active ImplaNtatE – project from the Collaborative Research Center 1270 headed by Prof. Dr. Hermann Seitz. As part of this project, scientists are experimenting with the production of bioactive bone implants by 3D printing.

Until now, titanium has often been used as a substitute material for bone. However, this can be difficult to adapt to individual anatomical conditions. In addition, titanium implants can loosen easily and thus cause long-term problems. An alternative therapeutic approach, is to remove bone material from the pelvis and transplant it to the damaged area. “But that is then additionally associated with another defect,” Seitz cautions. To be able to guarantee better implants with fewer side effects and better adaptation in the future, the ELAINE research group is making use of additive manufacturing and is on the way to treating bone defects with 3D printing technology.